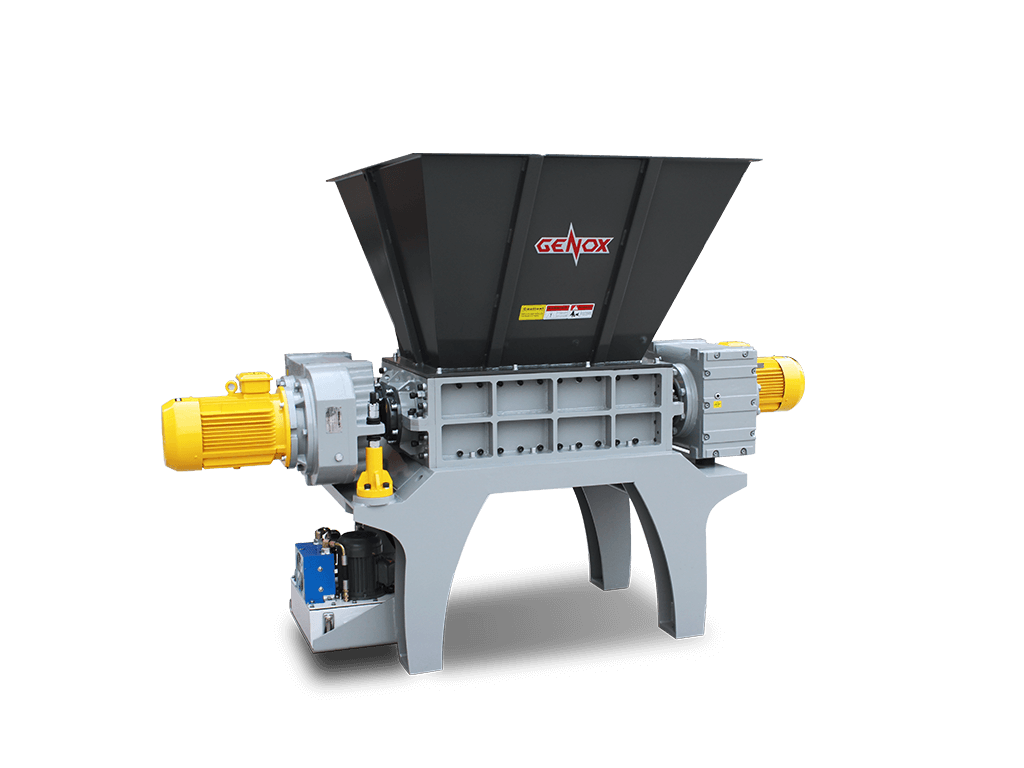

Low speed, high torque operation minimizes noise and power consumption – whilst achieving high throughput rates. These machines are particularly suited to the size reduction of bulky or voluminous materials which could include contamination such as metals or stones.

| Model | M300 | M400 | M600 | M800 | M800T | M1000 | M1200 | |

| Main Drive(kw) | 7.5 | 7.5 | 5.5+5.5 | 7.5+7.5 | 15+15 | 15+15 | 15+15 | |

| 18.5+18.5 | 18.5+18.5 | 18.5+18.5 | ||||||

| 22+22 | 22+22 | 22+22 | ||||||

| 30+30 | 30+30 | 30+30 | ||||||

| Rotation Diameter(Φmm) | 276 | 276 | 276 | 276 | 430 | 430 | 430 | |

| Shredding width(mm) | 400 | 500 | 600 | 800 | 800 | 1000 | 1200 | |

| Rotation Speed(rpm) | 13 | 13 | 14 | 14 | 5.4-12 | 5.4-12 | 5.4-12 | |

| 6.0-12 | 6.0-12 | 6.0-12 | ||||||

| 7.5-12 | 7.5-12 | 7.5-12 | ||||||

| 10-12 | 10-12 | 10-12 | ||||||

| Center distance(mm) | 210 | 210 | 210 | 210 | 320 | 320 | 320 | |

| Number of Blades | 15thickness | 20 | / | 40 | / | / | / | / |

| 20thickness | 15 | 20 | 30 | 40 | 40 | / | / | |

| 40thickness | / | 10 | / | 20 | 20 | 25 | 30 | |

| 50thickness | / | / | / | / | 16 | 20 | / | |

| 75thickness | / | / | / | / | / | / | / | |

| 100thickness | / | / | / | / | / | / | / | |

| The quantity of blade hocks | Standard rotor | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 | 1/2/3/6 |

| K type rotor | / | / | / | / | / | / | / | |

| D type rotor | / | / | / | / | / | / | / | |

| Dimension | L | 1500 | 1587 | 2530 | 2710 | 3055 | 3315 | 3574 |

| W | 1222 | 1222 | 1275 | 1275 | 1835 | 1885 | 1965 | |

| H | 1850 | 1850 | 1850 | 1850 | 2200 | 2200 | 2200 | |

| A | 1040 | 1140 | 1330 | 1530 | 1523 | 1723 | 1923 | |

| B | 1154 | 1154 | 1194 | 1194 | 1418 | 1418 | 1418 | |

| C | 604 | 604 | 643 | 643 | 875 | 875 | 875 | |

| D | 518 | 518 | 560 | 560 | 895 | 895 | 895 | |

| E | 840 | 940 | 770 | 970 | 1016 | 1216 | 1416 | |

| Weight | 1370 | 1470 | 2080 | 2300 | 4380 | 4520 | 5120 |