A PCB shredder is a specialized device for recycling printed circuit boards (PCBs), which are essential components in computer hardware responsible for connecting various elements. In the recycling process, shredding is the initial step that helps reduce size and facilitate the separation of different materials.In this blog post, we will provide an in-depth guide to PCB shredders, exploring their purpose, benefits, technologies, selection factors, and how they contribute to maximizing efficiency in electronic waste recycling.

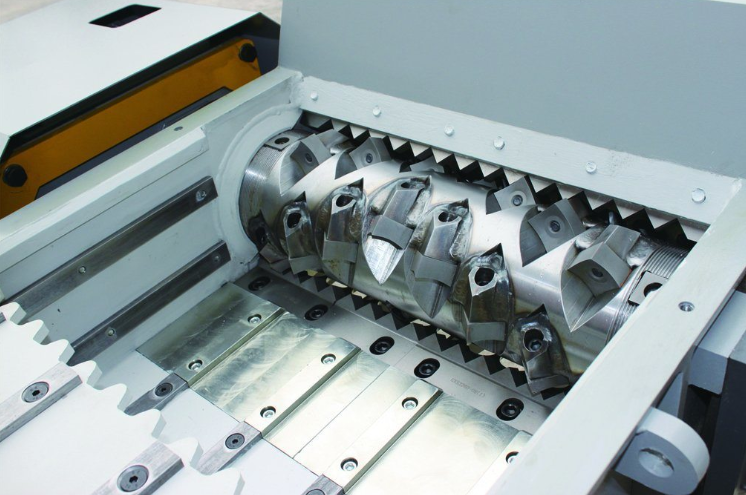

PCB shredding technology comes in various forms, each of which boasts distinct features. These designed elements are engineered to handle specific categories of e-waste.

Single-shaft Shredders:

These machines are perfectly suited for heavy-duty operations owing to their robust torque power. They employ a

low-speed, high-torque process to cut through resilient materials—ideal for disassembling robust PCBs.

The shredding process primarily involves cutting or grinding PCBs, achieved by the rotating blades of the shredder machine that tear the material apart. Some advanced shredders also incorporate separation technologies to segregate valuable components during the shredding process itself.

To choose the right PCB shredder, several aspects must be taken into account.

First, consider the volume of PCB e-waste, as it dictates the shredder's required size and power. Blade type, energy efficiency, and throughput rate are also significant factors. Moreover, specific demands for material separation, output size, and ease of maintenance influence the selection of a shredder.

Evaluate the shredder's capacity and throughput rate in relation to the amount of e-waste produced by your operation. Ensuring the shredder's compatibility with waste volume is vital not only for efficiency but also for machine longevity.

Power requirements and energy efficiency play a crucial role as well, as they impact operational costs and environmental footprint. Opt for a shredder that strikes the right balance between efficiency and power to meet your needs.

Finally, ensure the shredder melds seamlessly with your established recycling systems. Smooth integration helps avert bottlenecks and unnecessary operational expenses.

PCB shredders often offer customizable features to meet specific requirements. This includes options such as different blade types for varying material hardness, adjustable speed settings for desired throughput, and the ability to obtain different output sizes based on waste management needs. By selecting a shredder with the appropriate customization options, you can customize the machine to perfectly align with your operational needs.

Efficiency in e-waste management is not only about the shredding process itself but also how well the shredder integrates with your existing recycling system. Many modern shredders can connect with recycling systems for automated feeding and collection processes, reducing manual labor and boosting overall productivity. Shredders that can integrate with electronic waste separation systems or other downstream processing units can significantly streamline the recycling process.

Finally, while performance is key, it's important not to overlook safety, maintenance, and ease of operation. Customizable safety features can provide added assurance during operation, and easily-accessible components can simplify the maintenance process. User-friendly controls and interfaces can also make a big difference in day-to-day operations.

The V series sets itself apart with its energy efficiency, robust cutting force, and superior productivity. It comes equipped with features like a shock-absorbing gearbox, rotatable rotor knives, long-lasting counter knives, user-friendly screens that are easy to change, and a substantial control system. These elements work together to deliver remarkable performance, enduring durability, and seamless operation. In addition to these attributes, the V series is designed with integrated safety features and complies with CE standards. This commitment to safety and quality underscores the series as a reliable and secure solution for your PCB shredding needs.

Read more: V series specification for PCB recycling

The BH series excels in energy efficiency, impressive cutting force, and enhanced productivity. Equipped with features such as a shock-absorbing gearbox, rotatable rotor knives, long-lasting counter knives, easily replaceable screens, and a sturdy control system, it delivers outstanding performance, durability, and user-friendliness. Moreover, with integrated safety features and adherence to CE standards, the BH series provides a dependable and secure option for all your PCB shredding requirements.

Read more: BH series specification for PCB recycling

As the volume of electronic waste continues to increase globally, advancements in PCB shredding technology are more important than ever to drive sustainable and efficient recycling.

Advancements in PCB Shredder Technology are enabling more effective recycling by improving throughput, reducing energy consumption, and increasing the viability of reusable material extraction. Innovations in rotor design, motor efficiency, noise reduction, and particle size control are contributing to these improvements. Consequently, these advancements are pushing the boundaries of recycling possibilities, reclaiming more materials from e-waste, and reducing environmental impacts.

Emerging Trends, such as AI integration and automation, are propelling PCB shredding technology into a new era of efficiency. Artificial intelligence can optimize shredding parameters in real-time based on material input, reducing the need for manual adjustments. Automation can streamline recycling operations by coordinating shredding with subsequent stages of the recycling process. These advancements are poised to drive productivity while reducing labor requirements and error rates.

At Genox, we have been providing turnkey solutions for over 5 years. We specialize in manufacturing high-volume shredders and recycling machines for decades. They include “Shredder and Granulator Combo”, “Plastic Large Pipe Shredders”, “Lithium-Ion Battery Recycling Machines", “Fridge Shredders”, etc. If you would like to learn more about how we can design and manufacture a shredder or recycling machine for your project, please contact us!