When looking to purchase a lithium-ion battery recycling machine or system, it is critical that you have a thorough understanding that will allow you to make the best choice possible. We have some guides for you, whether you want to buy a small-scale or a large-scale system. We will introduce 8 basic guides about lithium-ion battery recycling machines and systems in this article.

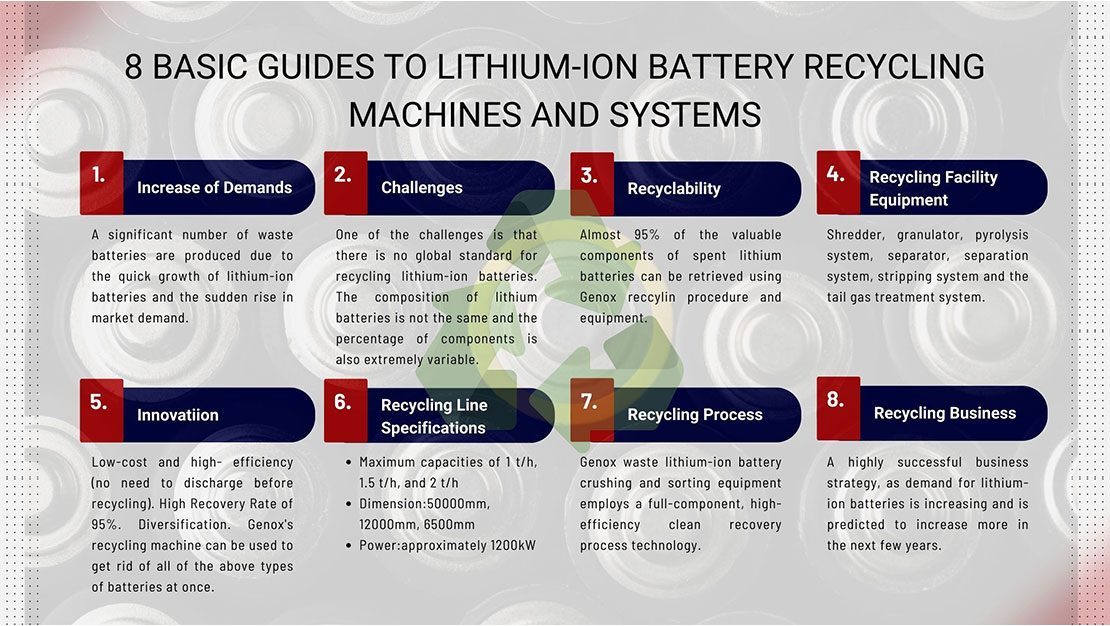

A significant number of waste batteries are produced due to the quick growth of lithium-ion batteries and the sudden rise in market demand, and some waste is also produced during the battery production process. Recycling such garbage in an eco-friendly, cost-effective, and efficient manner can not only eliminate the risks it poses to the environment and public health, but it can also supply raw materials for the manufacture of lithium-ion batteries, which will further cut down on resource use.

In order to effectively recycle the waste lithium-ion batteries, unique lines and sets of equipment for crushing and sorting waste lithium-ion batteries with advanced technologies are being developed and built.

Lithium-ion batteries contain metals such as nickel, cobalt, manganese, and lithium, as well as electrolytes and organic solutions. Improper disposal will not only cause major harm to the environment but also cause a great waste of resources. Due to the chemical reaction inside the battery and the increase in the ambient temperature, thermal runaway can easily lead to safety hazards such as combustion, fire, and explosion. It will pollute the environment and the human body with fluorine, organic matter, and heavy metals. As a result, it is more challenging to dispose of spent lithium-ion batteries.

The disposal process of waste lithium-ion batteries is relatively complicated, and it is necessary to deeply study the disposal process and the special equipment configuration under specific process conditions to make the complete set of equipment more green and environmentally friendly. Genox has created a comprehensive waste lithium-ion battery disposal process plan as well as a comprehensive set of trash lithium-ion battery crushing and sorting equipment. Almost 95% of the valuable components of spent lithium batteries may be retrieved using our procedure and equipment. These Includes separating the outer casing, copper, aluminum, black powder, etc.

We have been collaborating with WEEE recyclers all over the world to provide them with Li Ion Batteries Breaking and Separating Plants with innovative designs to efficiently and successfully recycle lithium ion batteries. We use advanced facilities, equipped with new technologies and research processes. We work with WEEE recyclers worldwide to give them a full set of equipment for shredding and sorting waste lithium-ion batteries with special technological procedures and new designs to dispose of used lithium-ion battery waste effectively and sustainably.

The new Waste Lithium-ion Battery Crushing and Sorting System adopts a dry treatment method for waste ion batteries. The entire procedure entails high-efficiency stripping, gen-controlled charged crushing, oxygen-controlled pyrolysis, sorting, and exhaust gas treatment for environmental protection.

Are you looking for a top-quality lithium-ion battery recycling machine? Here come the advanced features:

Typically, used lithium-ion batteries store or retain electrical energy. To maintain the safety of the crushing process, salt water or load discharge is typically employed, resulting in greater difficulties in the treatment of the discharge liquid, incomplete load discharge, and a lengthy period. Which leads to higher disposal costs and backward economic benefits.

The crushing and sorting equipment for Genox waste lithium-ion batteries uses an innovative design so that the lithium battery does not need to be discharged before crushing and that the entire crushing process is safe and stable, completely obstructing the possibility of explosion, combustion, and the diffusion of harmful gases. So that the entire crushing procedure is safe, effective, and cost-effective.

Neither the comprehensive recovery rate nor the quality of black powder obtained through the entire disposal procedure is less than 95%.

The New Lithium Ion (li-ion) Battery Recycling Machine is a type of recycling machine that is capable of full selection. It recycles different kinds of lithium batteries and can be used by many companies, such as those that make cell phones, laptops, and other electronic devices.

Lithium batteries are packaged in cylindrical, square, soft-pack, and hard shells. Ternary batteries include lithium iron phosphate, lithium cobalt oxide, and lithium manganate, among others. Genox has developed a complete set of equipment for crushing and sorting used lithium-ion batteries, which can be used to get rid of all of the above types of batteries at once.

Genox waste lithium-ion battery crushing and sorting equipment employs a full-component, high-efficiency clean recovery process technology. This complete set of equipment can meet the centralized disposal of lithium-ion batteries of different systems and specifications to the greatest extent.

The use of oxygen-controlled charged crushing technology in a protected atmosphere overcomes the environmental pollution problems caused by the typical discharge crushing process's extended duration and electrolyte leaking from damaged batteries. Following crushing, the product's particle size is uniform, the material is loose, and the wrapping phenomenon is absent.

Under a protective atmosphere, the adopted oxygen-controlled pyrolysis technology can select the process mode of retaining or pyrolyzing the diaphragm. By pyrolyzing the separator, the electrolyte and binder molecular chains can be completely broken, offering a pretreatment solution for further process requirements.

To meet the necessary emission limits, the pyrolysis gas is collected in a systematic way, entirely catalytically oxidized, and then fully burned.

The pyrolyzed material is sorted and stripped. It is possible to obtain valuable metals such as copper, aluminum, shell, and high-quality black powder.

The Li-ion battery recycling business is profitable since many companies have begun to employ this type of battery in their products. It is also a highly successful business strategy, as demand for lithium-ion batteries is increasing and is predicted to increase more in the next few years.

Lithium batteries are widely used in electric vehicles and electronic equipment. In recent years, the global demand for lithium batteries has grown substantially. However, the environmental damage caused by lithium batteries is increasing. Therefore, it is necessary to recycle and reuse these old lithium batteries, which has turned into a new area of development for many factories.

Please contact us today if you want to learn more about the success stories of lithium battery recycling machines in China and Europe, or learn more about E-waste Solutions : Understanding PCB Recycling, 3 trends of plastic pipe shredder and recycling machine, 10 Insights into Our Tire Shredding Machines : Shred Smart, Shred Versatile and new ultimate tool for plastic scrap reduction : shredder and granulator combo.