Printed Circuit Boards (PCBs) are essential parts of almost all electronic devices. As technology continues to progress, a growing number of devices containing PCBs are becoming waste. In order to reduce environmental damage and save valuable resources, it is important to carefully recycle these PCBs. This article will first explore all the aspects involved in PCB recycling and then focus specifically on the crucial role played by the PCB shredder - a key component in the recycling process.

Recycling Printed Circuit Boards provides numerous benefits. First and foremost, it supports the conservation of natural resources such as copper and aluminum, which reduces dependence on extensive mining activities. Moreover, recycling PCB helps decrease waste production and prevents the release of harmful materials into the environment. From a resource recovery standpoint, recycling PCBs enables the reuse of valuable metals, resulting in a significant decrease in the environmental impact associated with manufacturing processes.

There are several ways to recycle PCBs, including :

This process involves shredding, crushing, and separating various materials based on their specific physical properties.

This Involves size reduction, techniques such as shredding or grinding, and then employing separation techniques such as gravity-based or magnetic separation.

It enables efficient recovery of valuable metals, for example, gold, silver, copper and plastics.

This method may cause some loss of precious metals during the separation process.

Pyrometallurgical recovery utilizes high temperatures to separate and extract various metals.

This involves high-temperature operations such as smelting or incineration, to remove metals.

It is particularly effective in recovering base metals such as copper and tin.

This method may lead to the release of harmful emissions and the production of hazardous by-products.

Hydrometallurgical techniques use intricate chemical reactions and solutions to extract metals from the PCB.

This process involves chemical leaching to dissolve metals, followed by methods such as precipitation or electroplating to recover them.

It allows for high metal recovery rates and selective extraction of specific metals.

This technique requires the use of potentially toxic chemicals and appropriate waste treatment procedures.

This novel approach uses microorganisms or enzymes to extract metals from PCB selectively.

The process involves utilizing microorganisms or enzymes to selectively extract metals from PCBs.

It is an environmentally friendly and energy-efficient method, with potential for selective metal recovery.

This method is presently in the research and development stage, and has limited industrial-scale application.

| Method | Process | Benefits | Considerations |

|---|---|---|---|

| Mechanical Recycling | Size reduction and separation techniques | Efficient metal and plastic recovery | Some loss of precious metals during separation |

| Pyrometallurgical Recycling | High-temperature processes | Effective in recovering base metals | Emission of harmful substances, hazardous by-products |

| Hydrometallurgical Recycling | Chemical leaching and metal recovery processes | High metal recovery rates, selective extraction | Use of hazardous chemicals, proper waste treatment |

| Biotechnological Recycling | Microorganisms or enzymes-based extraction | Environmentally friendly, potential for selective recovery | Limited industrial-scale application, ongoing R&D |

The recycling process starts with the collection of discarded PCBs. This is then followed by an organized system of sorting and dismantling, employing the methods previously discussed.

Here is a detailed, step-by-step breakdown of the process :

This involves gathering the discarded PCBs.

The collected PCBs are categorized based on type and material composition.

The PCBs are then broken and their components segregated.

The separated components undergo processing, and the various materials are extracted.

The recovered materials are then reprocessed and prepared for future use.

The PCB recycling line consists of various components for efficient and effective recycling of electronic waste. Here we’d like to present a case study to provide a more comprehensive understanding of its working mechanisms.

The recycling line includes a 4-ton electronic waste sorting line, GES4000, along with a buffering hopper, GLD1260. After sorting, the material is then transferred using a vibrating conveyor or vibrating screen, LST1-010, which comes equipped with a tilted plate settling tank for sedimentation.

Following this step, the line utilizes a magnetic separator, MT6020, which separates magnetic materials from the mixture. The drum screening machine, TD1560, further sorts and screens the materials. The seamless operation also incorporates two conveyor belts, CBR80100L and CBR8080, to facilitate transportation within the recycling process. For precise separation and classification of materials, a Z-type separator, GZ1000-C, is put to use.

The PCB recycling line is also equipped with exhaust fans to control airflow and ventilation, ensuring a well-maintained environment throughout the process. These components work together to optimize the separation, sorting, and recovery of valuable materials from PCBs, enabling an efficient and environmentally friendly recycling process.

Learn more: Universal Washing System for mixed plastics from waste electronic appliances

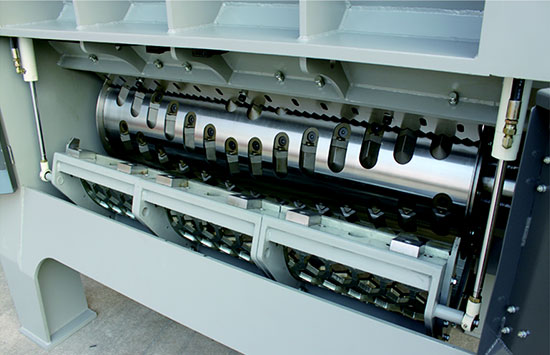

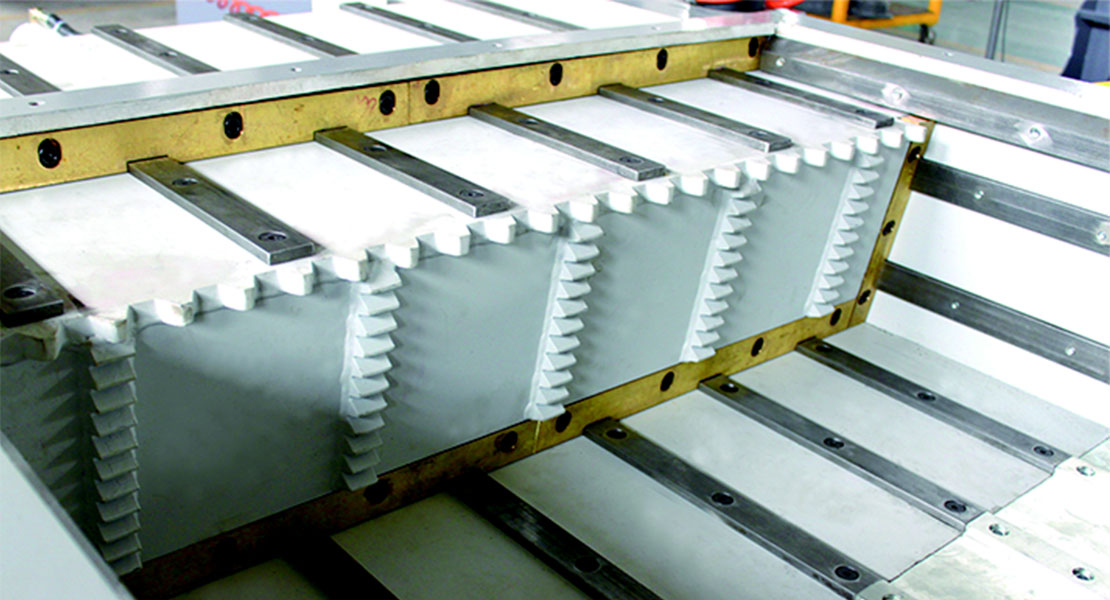

The PCB shredder is a fundamental part of the mechanical separation process. It efficiently breaks down PCBs into smaller pieces, making it easier to separate the different materials.

The primary function of the PCB shredder in the recycling process is to reduce the size of the PCBs into more manageable pieces. This shredding operation boosts the efficiency of subsequent separation stages by increasing the surface area accessible for metal recovery. In addition to this, the shredding process assists in the elimination of non-metal components, thereby streamlining the overall recycling procedure.

Read more: Wide Ranges of Shredders for E-Waste

The V Series Single Shaft Shredders are specifically designed for small to medium size reduction applications, making them ideal for PCB shredding. These machines are capable of processing a wide range of materials, resulting in a uniform particle size. The output products generated can be sold as they are or further processed using additional equipment like granulators or briquetters. The throughput capacity varies between 300kg/hr to 5,000kg/hr+ depending on factors such as the machine model, material type, screen size, and application requirements.

Read more: Specifications of V Series Single Shaft Shredder

In this blog, we've emphasized the importance of PCB recycling and the significant role the PCB shredder plays in the process. Genox offers custom PCB recycling machines and shredders that are designed with quality and efficiency in mind. As an ISO-certified manufacturer, we specialize in high-performance PCB recycling machines and turnkey solutions. Our expertise in this realm allows us to contribute to a cleaner and greener future by advocating responsible electronic waste management practices.

Partnering with a trusted supplier, known for their extensive history in plastic recycling machines, is an excellent starting point for your PCB recycling venture. If you are interested in learning more about PCB recycling or exploring our range of state-of-the-art PCB recycling machines and shredders, please visit our new blog, PCB Shredder Guides, or contact our knowledgeable team. Let's work together towards a sustainable, and eco-conscious approach to electronic waste management.

Learn more about our other recycling capability : Plastic Pipe Shrdding and Recycling, Shredder and Granulator Combo or Metal Recycling Shredders.