Welcome to our tire recycling world, where our special Tire Shredding Machines intelligently shred tires. This blog is your go-to guide to learn about how these innovative machines are transforming the tire recycling game. Let's explore 10 essential insights that illustrate how our tire shredding machines are revolutionizing how we handle old and scrap rubber tires.

Our tire shredding machines adapt effortlessly to various tire categories – from compact cars (PCR) to off-the-road vehicles (OTR) and heavy-duty trucks (TBR). This versatility ensures a comprehensive and efficient tire recycling process.

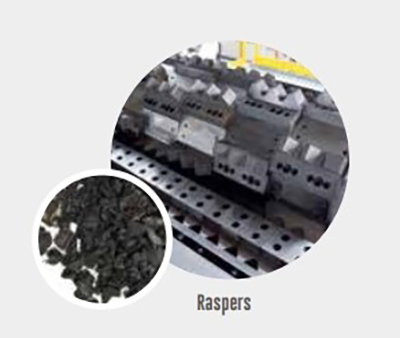

The advanced two-stage rasper system in our tire shredding machines is a standout feature, liberating steel from rubber, ensuring effective separations, and facilitating the production of clean wire. This innovation enhances recycling efficiency and contributes to high-quality recycled materials. The rubber's purity can reach up to 99%.

Explore the heart of our tire shredding machines – the precision-crafted blades. With a meticulous ten-plus-step process, these blades strike the perfect balance between hardness and strength, defining the longevity and performance of our machines.

Our tire shredding machines provide a comprehensive solution through the incorporation of both "Primary Shredders" and "Secondary Shredders." This dual-shredder approach ensures an efficient tire recycling process at different stages, allowing for a more thorough and versatile processing of tires. Here's a breakdown of their distinct roles:

Discover the diverse applications of our tire shredding machines across various industries – from landfills to insulation, agriculture to construction, manufacturers to rubber recyclers, and the automotive industry.Our rubber shredder technology further expands our footprint in the recycling landscape.

Uncover the critical considerations in tire shredding machine production – the delicate balance between blade hardness and strength. This balance is crucial for optimizing the lifespan and performance of our tire shredding machines.

Our blades aren't just blades ; they result from a proprietary manufacturing process in collaboration with state-owned enterprises. This unique approach ensures that our tire shredding machines are equipped with blades crafted for maximum efficiency and durability.

Addressing a crucial buyer concern, our tire shredding machines are engineered to meet and exceed expectations in production capacity, making it the first question buyers ask and showcasing our readiness to deliver.

Witness the seamless orchestration of our tire shredding machines, including advanced automatic tyre recycling systems, through advanced system automation. This links components' actions, maximizing system capacity, and protecting against interfering materials.

Experience tire recycling in a quieter environment with our advanced sound attenuation enclosures, now designed to accommodate automatic tyre recycling and scrap tire recycling features. This reduces noise levels to < 85dBA, enhancing working conditions and aligning with environmental standards.

Under the guidance of our tire shredding machines, there has been a significant transformation in the way tire recycling is approached. These 10 insights reveal how our intelligent and versatile tire shredding machines play a crucial role in realizing sustainable tire recycling practices. If you want to dive deeper into our innovations in tire shredding machines, the two-stage rasper system, and the achievement of up to 99% rubber purity, explore our Tire Recycling Machine Line System product page, or discover our other product lines, including PCB Recycling, Metal Recycling Shredders, Shredder and Granulator Combo, Plastic Pipe Shredder, Fridge Shredder. If you are ready to start up your tire shredding machine, please contact us today.