Plastic pipes have become an integral part of modern construction and manufacturing, but their disposal has long been a challenge. Landfills are overflowing with plastic waste, and the environmental impact of this waste is significant. That's where plastic pipe shredder and plastic pipe recycling machine come in. These machines shred large plastic pipes into smaller pieces, which can then be recycled in a closed-loop system.

As the demand for plastic pipe shredding and recycling machines continues to grow, there are several key trends that are expected to emerge in the coming years. These trends are driven by the need to increase capacity, flexibility, and the ability to process all plastic materials, and they are likely to have a significant impact on the industry.

One of the main trends in plastic pipe shredding and recycling machines is the increasing demand for large-capacity machines. As the use of plastic pipes continues to grow, so does the amount of waste plastic that needs to be processed. To meet this demand, manufacturers are developing larger and more powerful shredders that can handle larger volumes of material and operate at higher speeds. These machines are typically equipped with advanced features such as multiple cutting blades, high-torque motors, and automatic feed systems, which enable them to process more material in less time.

Another trend in the market for plastic pipe shredding and recycling machines is the growing demand for flexible machines that can handle different sizes of plastic pipes. As the need for plastic pipe recycling increases, it is important for these machines to be able to adapt to a wide range of pipe sizes in order to effectively process and recycle these materials. This trend is expected to continue as more and more plastic pipe manufacturers and recyclers look for solutions that can help them reduce waste and improve their environmental footprint.

The trend toward machines that are capable of processing all plastic materials is also gaining momentum. In the past, plastic pipe shredding and recycling machines were typically designed to handle only one or two types of plastic, such as PVC or HDPE. However, as the market evolves and the demand for recycled plastic increases, manufacturers are developing machines that can handle a wider range of materials. This includes machines that can process mixed plastics, as well as those that can handle a variety of different colors and grades of plastic. These multi-purpose machines are designed to provide maximum efficiency and flexibility.

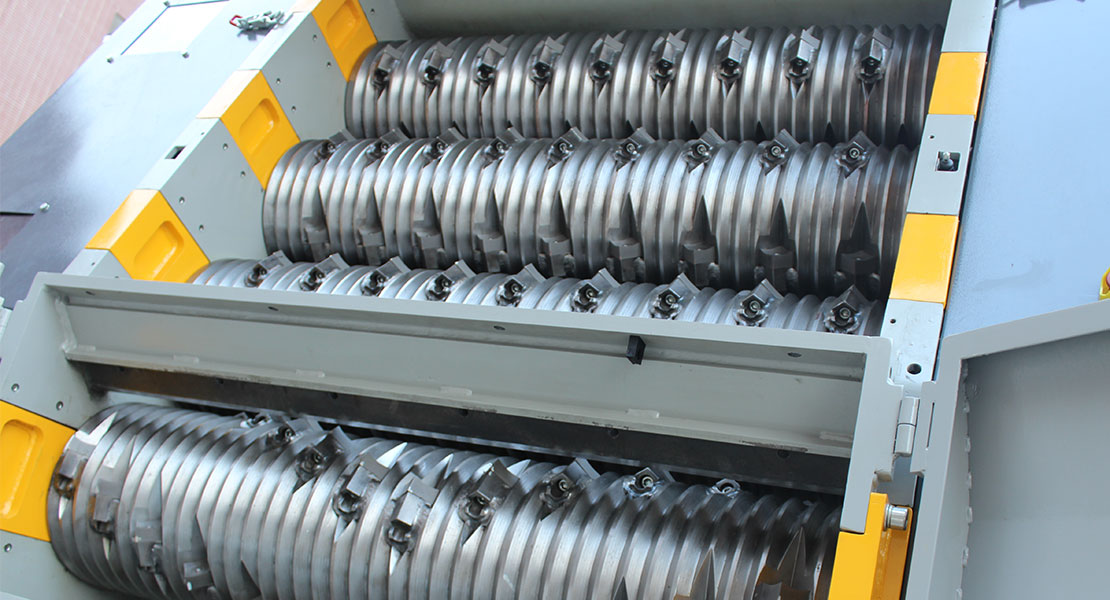

The Large Plastic Pipe Shredder Genox J1200 is the largest machine in our plastic pipe shredding line. The combination of its ultra-long span cutting chamber and multi-rotor design allows this machine to be used for any plastic pipe recycling projects. This large shredder is designed with special counter knives, a segmented loading chamber floor with a brass guide, and long-life counter knives that help ensure that your material will maintain a high level of performance and efficiency at all times.

An ultra-long volume cutting chamber that can break 6 meters long materials — this will allow you to shred long pieces of pipe or profile into shorter pieces faster than ever before!

The number of rotors can be specified according to the material size. This allows for optimal cutting efficiency and performance by minimizing power consumption.

High shear cutting between the rotor and counter knives, suitable for thin wall pipe shredding. This helps keep the blades sharp and efficient at all times, meaning less downtime and greater productivity

Long-life counter knives can be adjusted to maintain cutter clearance, so you don't have to worry about replacing them as often as other types of shredders might require.

Segmented loading chamber floor with brass guides ensures that even small pieces will fit into the machine without issue or jamming up the system (which means less waste!).

A large feed with a hydraulic tipper for optimized material loading - ensures that all materials are fed evenly into the shredder without jamming or clogging up internal components.

J series pipe shredders have been supplied to clients primarily from Mainland China, Australia, Cambodia, the U.S., and Africa. All the clients mentioned above ordered the whole recycling line with the J series shredder machine (J1200/J800) as the chief component. Among all the customers, APPLIED MACHINERY AUSTRALIA PTY LTD has ordered the pipe recycling line several times in the year 2021. The success of our J series shredders in these regions highlights their versatility and efficiency in handling a wide range of plastic materials.

There is also a good sales record in South America, particularly with our another V series shredders and recycling systems in the recent two years. Involved countries, including the followings: Bolivia, Colombia, Ecuador, Brazil, Venezuela, and Chile. We are dedicated to expanding our global presence and bringing our innovative solutions to new markets around the world, and we believe that our J series pipe shredders have the potential to be successful in the South American market in the coming years.

Further reading: How Does Plastic Large Pipe Shredding and Recycling Promote Sustainability and Circular Economy?

Genox is a high-end Chinese manufacturer of solid waste recycling machinery and equipment, including plastic pipe shredders, grinders, and granulators. We design and manufacture large-capacity industrial shredders to meet all your plastic pipe recycling demands. You can get a total solution at once from Genox. To learn more about our pipe shredder capacity, please contact us today. To discuss your recycling projects with one of our team members, please call us right now. For more shredding recycling machines for large pipes, please refer to Large Pipe Shredders.

To keep updated about the latest news from the Genox, please follow us on our social media channels:

Genox YouTube : Recycling Solutions

Or you can also read more blogs about The Right Shredder for Highest ROI, 8 Basic Guides to Lithium-Ion Battery Recycling Machines and Systems and Shredder and Granulator Combo.