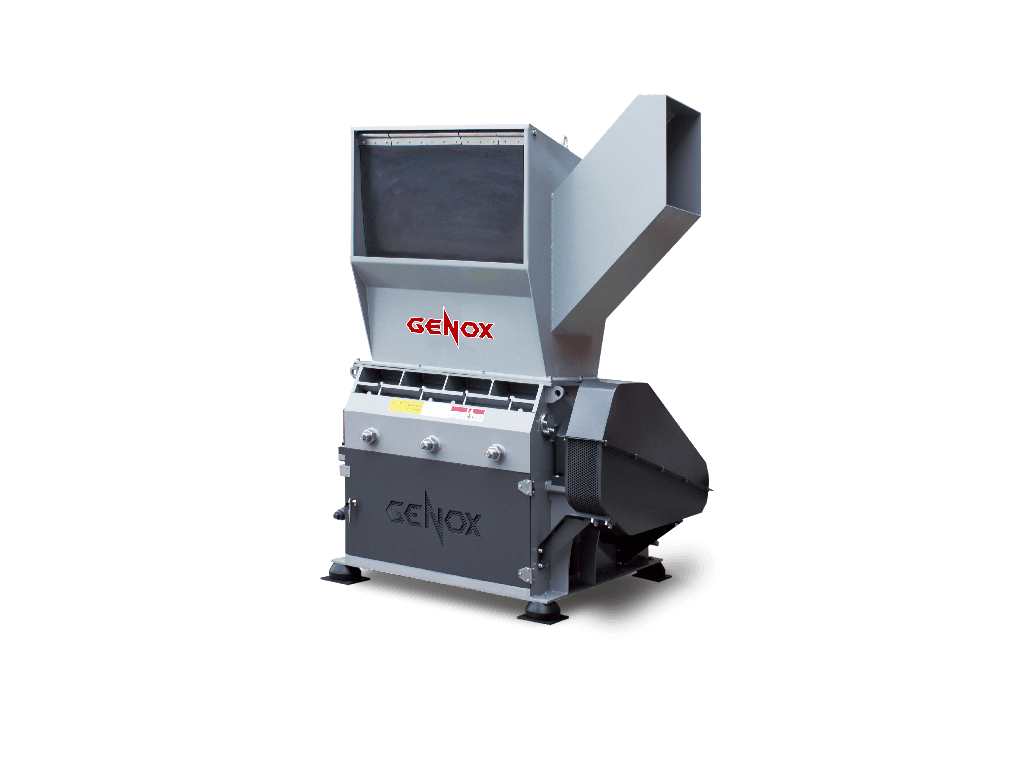

GC Series Granulators are high speed granulation machines designed especially for the efficient size reduction of various materials in a single pass.

These machines are ideal for processing a multitude of materials including plastics, rubber, fibers, copper cable and light non-ferrous metals amongst others.

| Model | GC600T | GC800 | GC800T |

| Dimension (L x W x H) (mm) | 1435 × 1177 × 2397 | 1435 × 1377 × 2397 | 1641 × 1450 × 2471 |

| Hopper Opening (L x H) (mm) | 552 × 747 | 752 × 747 | 800 × 815 |

| Rotation Diameter (mm) | Φ320 | Φ320 | Φ418 |

| Operation Length (mm) | 616 | 816 | 816 |

| Rotation Speed (RPM) | 580 | 580 | 580 |

| Screen Size(mm) | Φ12 | Φ12 | Φ12 |

| Number of Rotor Knives | 3×2 | 3×2 | 3×2 |

| Number of Counter Knives | 2×1 | 2×1 | 2×1 |

| Main Drive (kW) | 22 | 30 | 37 |

| Weight(kg) | Approx 1519 | Approx 1749 | Approx 2441 |