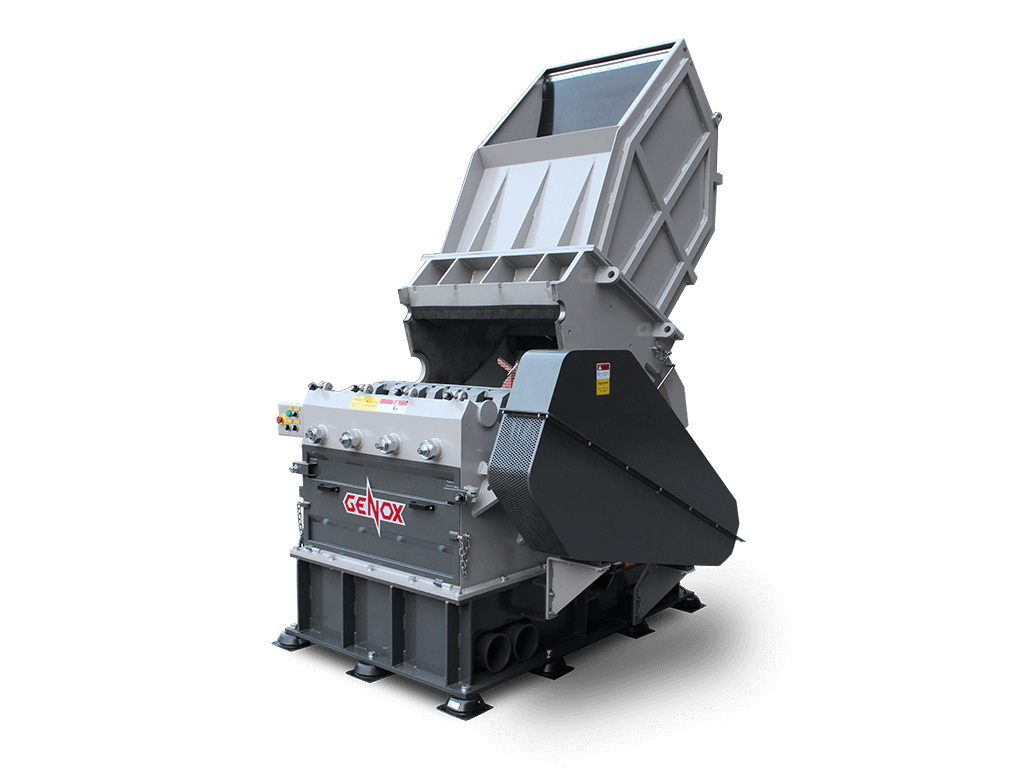

GXC Series Heavy Duty Granulators with power ratings of 55kw to 315kw are designed for high throughput processing. With a variety of rotor configurations available, these granulators have a wide range of applications including; hollow and voluminous materials (i.e. plastic drums, crates and chairs), flexible materials such as films, woven bags and rubber, tougher materials such as profiles, thick sheets, and other general plastics.

| Model | GXC800 | GXC1200 | GXC1200T | GXC1600T | GXC1200G | GXC1600G | GXC2000G |

| Dimension (L x W x H) (mm) | 2166 × 1802 × 3141 | 2166 × 2202 × 3141 | 2474 × 2257 × 3403 | 2496 × 2666 × 3373 | 2603 × 2503 × 3902 | 2650 × 2870 × 3900 | 2920 × 3304 × 3877 |

| Hopper Opening (L x H) (mm) | 752 × 820 | 1152 × 820 | 1152 × 1020 | 1552 × 1020 | 1200 × 1113 | 1560 × 1150 | 2014 × 1146 |

| Rotation Diameter (mm) | Ø 502 | Ø 502 | Ø 660 | Ø 662 | Ø 808 | Ø 800 | Ø 800 |

| Operation Length (mm) | 816 | 1216 | 1216 | 1616 | 1216 | 1600 | 2020 |

| Rotation Speed (RPM) | 520 | 520 | 520 | 520 | 460 | 480 | 460 |

| Screen Size(mm) | Ø 12 | Ø 12 | Ø 12 | Ø 12 | Ø 12 | Ø 12 | Ø 12 |

| Number of Rotor Knives | 5×2 | 5×2 | 7×2 | 7×4 | 9×2 | 9×4 | 9×4 |

| Number of Counter Knives | 1+2 | 2+4 | 2+4 | 2+4 | 2+4 | 3×2 | 4+8 |

| Main Drive (kW) | 55 | 75 | 90 | 132 | 110 | 160~250 | 220 |

| Hydraulic Power Pack(kW) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Weight(kg) | Approx 4103 | Approx 5068 | Approx 6891 | Approx 9802 | Approx 10242 | Approx 11800 | Approx 14347 |